CNC Machining is a prominent manufacturing process that is used to create a wide range of products.

Milling is one of the most common machining processes. In this article, we will answer the many questions you have about CNC milling like, what is CNC milling? What are the parts of a CNC milling machine? And what materials can be milled?

Read on to learn more!

What Is CNC Milling, and What Are its Uses?

CNC stands for computer numerical control- and that’s exactly what this technology does: it controls the movement of a milling machine using numerical code. This type of milling is perfect for creating precision parts and components out of metal, plastic, or other materials.

How Does a CNC Milling Machine Work?

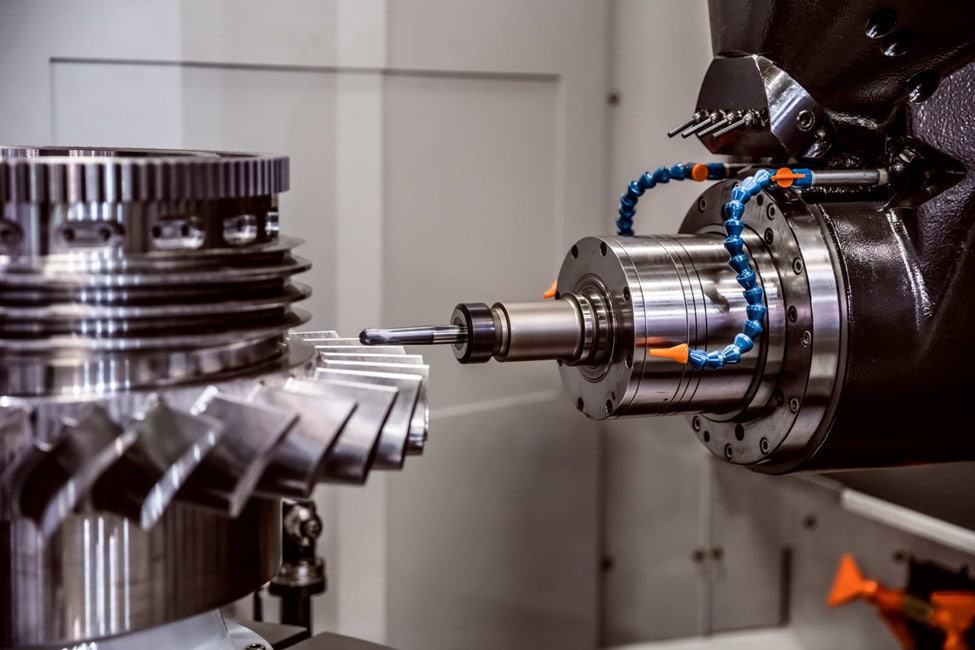

CNC milling machines use a variety of cutting tools to shape materials. The most common type of tool is a rotary cutter, which is a bit like a drill bit. The cutter is mounted on a spindle, which spins at high speeds. The cutter moves along the X and Y axes to create the desired shape.

The Z axis is used to control the depth of the cut. This can be important for creating intricate shapes, as it allows you to plunge the cutter into the material as needed.

What Materials Can be Milled With a CNC Machine?

Just about any type of material can be milled with a CNC machine. This includes metals, plastics, wood, and even glass. In fact, CNC milling is often used to create custom jewelry or other small objects made from precious materials.

What Are the Advantages of Using a CNC Milling Machine?

There are many advantages to using a CNC milling machine. Some of the most notable include:

-Precision: CNC milling produces parts with extreme precision, making it an ideal choice for high-precision applications.

-Speed: CNC mills can achieve very high speeds, allowing you to quickly produce large quantities of parts.

-Ease of Use: CNC milling is a relatively easy technology to learn. This makes it a good choice for beginners or for anyone who wants to quickly produce parts without having to learn complex CAD software.

-Versatility: CNC mills can be used to create a wide variety of shapes and components.

-Cost-Effectiveness: CNC milling is a cost-effective way to produce parts in small or large quantities.

What Are the Benefits of Using a CNC Milling Machine in Your Business or Workshop?

There are many benefits of using a CNC milling machine in your business or workshop. Here are just a few:

-Increased Productivity: CNC milling machines can help you increase productivity by allowing you to quickly produce large quantities of parts.

-Improved Quality: CNC milling produces parts with extremely tight tolerances, ensuring high-quality products.

-Reduced Costs: CNC milling is a cost-effective way to produce parts in small or large quantities.

How to Choose the Right CNC Milling Machine for Your Needs

There are a few things to consider when choosing the right CNC milling machine for your needs. Some of the most important factors include:

-The type of materials you want milled

-The size and complexity of the parts you need to produce

-Your budget

If you’re looking for a high-quality CNC milling machine that can handle a wide variety of materials and parts, Starrapid is a CNC manufacturing company you can trust. They offer a wide range of manufacturing services to meet the needs of businesses of all sizes.

The Basics of CNC Machining

Now that you know a little about CNC milling, let’s inspect the basics of CNC machining.

Creating a CAD File

The first step in CNC machining is creating a CAD file. This file will generate the toolpaths that the machine will follow. There are many software programs that can be used to create CAD files. Some of the most popular include AutoCAD, Solidworks, and CATIA.

Once the CAD program has been chosen, a 3D model is created of the part you want to mill. This is done by either scanning an existing part or creating a new design from scratch.

How to Set Up the Toolpaths

The next step in CNC machining is setting up the toolpaths. This is done by using a CAM (computer-aided manufacturing) program. A CAM program is used to generate the code that will tell the machine what movements to make and what speed to travel at.

There are many CAM programs available, but some of the most popular include Mastercam and GibbsCAM. These programs allow you to create a wide variety of toolpaths, including contour, pocketing, and drilling.

Once the toolpaths are set, they can be exported to a G-code file. This file can then be used to run the machine.

How to Run the CNC Machine

Now there’s a G-code file, the machine is ready to run. First, the file is loaded into the machine’s controller. The controller is the brain of the machine and is used to interpret the G-code and send signals to the motors.

Once the file is loaded, the machine can be started and will begin to create your part. Depending on the complexity of the part, it may take a few minutes or hours to complete.

Conclusion

CNC machining is a versatile and cost-effective way to produce parts. With the right machine and software, you can quickly create high-quality parts in small or large quantities.