These days, we live in a dynamic business world where technological advancements are driving industries to seek innovative solutions for improving the efficiency and functionality of their products.

Great examples of such innovative solutions in manufacturing are heat sinks and laser cutting technology. Let’s check what makes them powerful and how they can contribute to improving manufacturing efficiency.

What are the key benefits of laser-cutting technology?

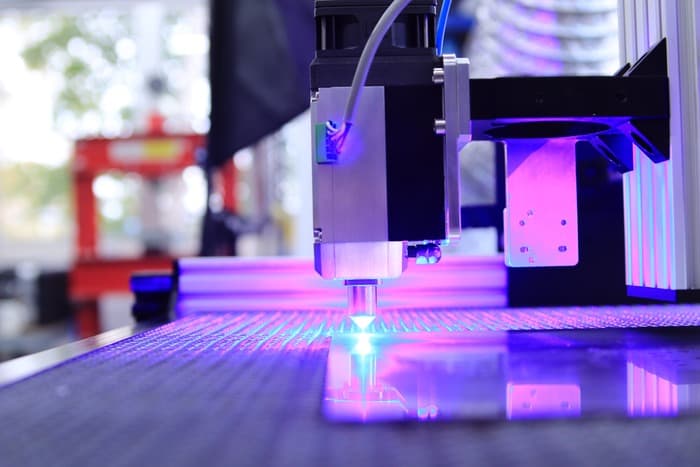

In fact, laser cutting technology has been revolutionizing the precision industry for some time now. It entails using a high-powered laser beam to precisely cut or engrave materials with incredible accuracy.

The benefits of using laser cutting are, among others:

- material versatility: it can be applied to a wide range of materials, including metals, plastics, or wood,

- high precision: the technology offers exceptional precision, allowing for intricate designs,

- high-speed: it significantly speeds up the manufacturing process, which makes it suitable for mass production,

- minimal waste: the technology produces minimal waste, thanks to its accuracy and efficiency.

What is the power of heat sinks?

In many applications, especially those involving high-performance electronics and machinery, heat management is crucial to avoid overheating and potential damage.

In such cases, heat sinks can ensure that heat is dissipated efficiently and the manufacturing process is well organized.

They are passive thermal management elements designed to transfer heat away from a hot source, typically a semiconductor device or electronic component.

Conventional heat sinks come in various shapes and materials (for example, aluminum and copper). As a result, they provide effective thermal dissipation through natural convection and conduction.

It is worth mentioning, though, that engineers are continuously innovating heat sink designs to enhance their heat dissipation capabilities and reduce their size and weight.

What are the use cases for laser cutting technology and heat sinks?

Truth be told, to fully boost the efficiency of manufacturing processes within businesses, you can take advantage of the collaborative forces of these technologies using laser-cut heat sinks.

They can be applied in various industries for numerous use cases, for example:

- Electronics, where they are essential to cool processors and graphics cards in gaming laptops and desktops,

- Automotive: to efficiently cool down systems in electric vehicles and high-performance engines,

- Aerospace, where complex geometries made possible by laser cuts can help maintain temperature control in spacecraft and aviation systems.

All in all, laser cutting and heat sinks are innovative technologies that can boost the manufacturing process performance. By harnessing the precision of laser cuts to craft custom heat sinks, businesses can achieve superior thermal management solutions, creating more high-performing devices.