Quality control is paramount to ensure the accuracy and reliability of results for maintaining the trust of patients and healthcare providers. However, the complexity of laboratory operations can make it challenging to identify and correct errors. This is where Laboratory Information Management Systems (LIMS) can help. It is important to note that multiple LIMS providers are in the market. A laboratory should carefully evaluate and choose a system that meets its needs and requirements through thorough research and due diligence.

This article will discuss how LIMS software can ensure quality control in the medical diagnostic laboratory and the benefits of implementing such a system. Let’s explore the various aspects of quality control in a laboratory and how LIMS can be used to manage and maintain it.

Quality Control in a Laboratory

Quality control in a laboratory is a systematic approach to monitoring and maintaining the accuracy and precision of laboratory testing. Quality control ensures that laboratory results are accurate, reliable, and consistent. It can be ensured by implementing a series of checks and balances throughout the testing process, from sample collection to reporting. Now that we know what quality control is, let’s move to why it is important.

Why Quality Control is Important in a Laboratory

Some of the reasons why quality control is essential in a laboratory are-

- Accurate and reliable laboratory results are essential for patient care. Incorrect test results can lead to misdiagnosis, inappropriate treatment, and patient harm.

- Quality control is necessary for regulatory compliance. Accrediting organizations require laboratories to demonstrate that they have a quality control program in place.

- The Clinical Laboratory Improvement Amendments (CLIA) in the USA and National Accreditation Board for Testing & Calibration Laboratories (NABL) in India follow quality standards and provide voluntary accreditation services to laboratories.

- Quality control is essential for maintaining the reputation of the laboratory.

A laboratory that consistently produces inaccurate or unreliable results will quickly lose the trust of patients and healthcare providers. As we already know, the accuracy and reliability of laboratory results are critical to patient care and to make treatment decisions, healthcare providers rely on laboratory results to make informed decisions.

Internal Quality Control

Internal quality control refers to the processes and procedures a laboratory uses to monitor the accuracy and precision of its testing methods. This includes using control samples, which are samples with known values that are run alongside patient samples, to ensure that the testing system is working correctly. Internal quality control also involves using quality control charts to monitor trends in test results over time.

External Quality Control

External quality control involves using external agencies to monitor and evaluate the quality of the laboratory’s testing procedures. This is done by participating in external proficiency testing programs where the laboratory’s results are compared to those of other laboratories.

Quality Control Charts

Quality control charts are graphical tools used to monitor the performance of the laboratory’s testing procedures and test results trends over time. They allow a laboratory to identify systematic errors in its testing methods, such as shifts or trends in the mean or standard deviation of test results. By monitoring quality control charts, a laboratory can identify when a testing system is out of control and take corrective action. Additionally, they provide a visual representation of the laboratory’s performance and help to identify any trends or patterns that may be emerging.

Quality control is essential to ensure accuracy and reliability. By implementing rigorous quality control procedures, laboratory professionals can detect errors early on and take corrective measures to minimize their impact. However, laboratory errors can still occur even with proper quality control measures. Therefore, it is crucial to have robust error detection and minimization strategies to prevent errors that can cost laboratories heavily on their reputation. The following part covers sources of errors and the detection of errors.

Detecting and Minimizing Laboratory Errors

One of the critical aspects of error detection and minimization is the implementation of effective quality control measures. This includes monitoring laboratory equipment performance, regularly checking and calibrating instruments, and establishing standard operating procedures for every test or analysis.

Additionally, laboratory professionals should regularly review test results and perform root-cause analyses to identify the underlying causes of errors and prevent them from happening again. The next part of the article covers the sources of laboratory errors and ways to identify and minimize them.

Sources of Laboratory Errors

Laboratory errors can be classified into three main categories: pre-analytical, analytical, and post-analytical.

- Pre-analytical errors occur before the testing process begins and include issues such as mislabeling of samples, incorrect patient identification, and improper sample collection and handling.

- Analytical errors occur during the testing process and include issues such as instrument malfunction, improper calibration, and operator error.

- Post-analytical errors occur after the testing process is complete and include issues such as data entry errors, misinterpretation of results, and incorrect reporting.

Laboratory Quality Management Software Systems (QMS)

A quality management system (QMS) is a comprehensive system that outlines the policies, procedures, and processes required to ensure consistent, high-quality laboratory results. LIMS can also be used as a quality management software system.

What Is a Quality Management System in a Medical Laboratory?

In medical laboratories, a quality management system is a set of policies, procedures, and processes used to ensure the quality of laboratory testing. It includes procedures for sample handling and processing, instrument calibration and maintenance, and data management and analysis.

Role of QMS in Quality Management

A laboratory quality management system plays a crucial role in ensuring the reliability and accuracy of laboratory testing. It provides a framework for the laboratory to monitor and evaluate its performance and take corrective actions when necessary.

Lab Procedures Where LIMS can be used for Quality Control

One way that QC lab managers can improve the quality control procedures in the laboratory is by using Laboratory Information Management Systems (LIMS). LIMS is a software solution designed to manage laboratory data and processes, including sample tracking, data capture, and reporting. Some of the quality control procedures include the following:

Sample Tracking

LIMS can be used to track samples as they move through the laboratory. This ensures that samples are properly labeled and the testing process is followed correctly.

Chain of Custody

LIMS can be used to maintain the chain of custody of samples. This ensures that the samples are handled correctly and the results are reliable. LIMS can also help automate the flow of samples with correct delegation to relevant personnel from collection to disposal.

Lot Release

LIMS can be used to release lots of reagents and other materials used in the laboratory. This ensures that the materials used are high quality and that the testing process is accurate and reliable.

Traceability

LIMS can be used to maintain the traceability of samples and testing procedures. LIMS software can trace each sample and its associated data, including test results, raw data, and audit trails.

Investigations into Atypical Results

The results that fall outside the expected range or pattern are known as atypical results or outliers. Various factors cause these results, such as errors in sample preparation, instrument malfunction, or operator error. LIMS software can help identify atypical results and facilitate the investigation process to identify the source of the error.

Identify Trends in Performance

LIMS can identify trends in the laboratory’s performance over time. It can analyze data over time to identify trends and ensure that the laboratory meets performance metrics. This allows QC lab managers to identify areas that need improvement and take corrective actions.

Results Entry

LIMS can be used to automate entering results into the system. This reduces the risk of data entry errors and ensures that the results are accurate and reliable. LIMS software can automate the entry of results and reduce the risk of errors caused by manual data entry.

Maintain Data on Instrumentation

LIMS can be used to maintain data on instrumentation used in the laboratory. LIMS software can track instrument performance data, such as calibration and maintenance records, to ensure that instruments operate at peak performance levels.

Automate Instrument Calibration

LIMS can automate the process of instrument calibration. LIMS software can automate instrument calibration schedules, ensuring that instruments are calibrated at appropriate intervals. Calibration and maintenance of instruments maintain accuracy in testing.

Automate Routine Tasks

LIMS can be used to assist overburdened lab staff by automating routine tasks. This frees up time for the team to focus on more complex tasks and ensures that the testing process is accurate and reliable.

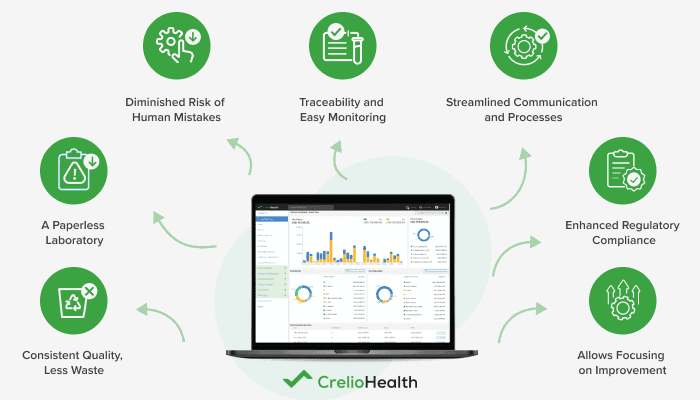

LIMS Advantages That You Should Know!

LIMS is a software solution that helps to manage laboratory data, processes, management, and operations. Multiple advantages make LIMS an essential tool for quality control in the laboratory. Let’s get a thorough understanding of some of the advantages of LIMS.

Consistent Quality, Less Waste

The most significant advantage of using LIMS software in a laboratory setting is that it can help ensure consistent quality and reduce waste. LIMS software can help ensure that laboratory processes are standardized and efficient, and reduces the risk of errors while improving the quality of results.

A Paperless Laboratory

Another advantage of LIMS software is that it can help laboratories become paperless. By eliminating paper-based workflows, laboratories can save time and reduce the risk of errors. Additionally, a paperless laboratory can help reduce the environmental impact of laboratory operations.

Diminished Risk of Human Mistakes

LIMS software can also help reduce the risk of human errors in laboratory processes. By automating workflows and providing real-time data entry and analysis, LIMS software can help ensure that laboratory processes are carried out consistently and accurately.

Traceability and Easy Monitoring

LIMS software also provides traceability and easy monitoring of laboratory processes. Providing real-time data entry and analysis helps laboratory managers track progress in achieving quality goals, identify areas for improvement, and ensure that processes are consistent and efficient.

Streamlined Communication and Processes

In a laboratory, multiple departments must work together to ensure that tests are performed accurately and efficiently. LIMS software helps in collaborating and improving communication between departments, streamlining processes, and reducing the risk of errors. For example, sample tracking is automated and easily monitored, so laboratory staff can quickly identify issues and take appropriate action.

Enhanced Regulatory Compliance

Regulatory compliance is an essential consideration for any laboratory. LIMS software can help ensure that the laboratory complies with regulatory requirements, reducing the risk of fines and penalties. For example, LIMS can ensure that all documentation is accurate, up-to-date, and easily accessible. Additionally, LIMS can automate processes such as sample tracking, result entry, and instrument calibration ensuring all processes are performed consistently and accurately.

Allows Focusing on Improvement

LIMS software can help allow laboratory staff to focus on improving processes and procedures, resulting in continuous improvement and better quality control. By automating recurring functions such as sample tracking and result entry, LIMS can reduce the workload on laboratory staff, allowing them to focus on more complex tasks. Additionally, LIMS can provide detailed analytics and reports, allowing laboratory staff to identify trends and areas for improvement.

Conclusion

LIMS is a powerful quality management software system that can significantly improve quality control in laboratories. Routine task automation, traceability, easy data monitoring, and analysis make it the right choice for lab owners to maintain quality while scaling their businesses. From the blog, it is clear that laboratories that implement LIMS can benefit from improved quality control management, increased efficiency, reduced costs, and improved regulatory compliance.

LIMS is just one part of a comprehensive laboratory quality control management system that includes policies, procedures, and processes used to ensure the quality of laboratory testing. By implementing LIMS and a comprehensive QMS, laboratories can provide accurate and reliable results, which is essential in healthcare setups.